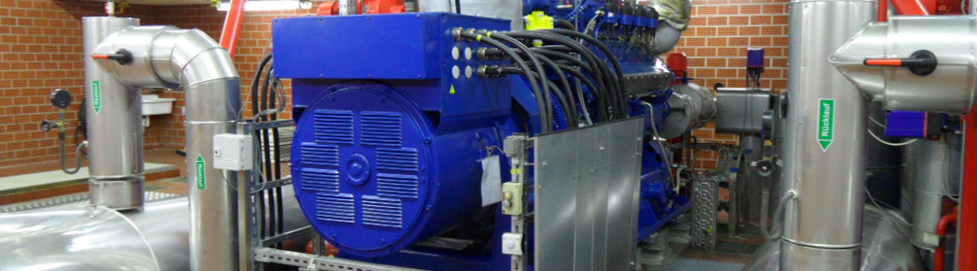

Block heating and power station

The gas itself is a mixed gas which combines digester gas from the treatment plant, biogas from ALBA Niedersachsen-Anhalt GmbH’s bio-waste fermentation facility, and gas from the waste disposal site in Watenbüttel and the biogas plant in Hillerse.

This is how it works:

In the first step, the four assorted energy-rich gases are fed into the mixed gas storage facility. Here, the methane content, which is different for each of the four gases, is adjusted to the same level. The methane content is then around 50 per cent.

The resulting mixed gas subsequently flows through the gas purification facility (activated charcoal filter) in which the trace substances, which are harmful for the environment and the gas engines, are removed. Following purification, the gas is converted into electricity.

The resulting electricity is utilised to supply the entire treatment plant with electricity. The quantities of mixed gas delivered and produced mean that the treatment plant functions completely self-sufficiently as regards energy – more energy is produced than is required. The waste heat from the engines and the exhaust heat are used for heating purposes in the treatment plant itself as well as at the ALBA Niedersachsen-Anhalt GmbH’s bio-waste fermentation facility.